NEWS RELEASE

SIGNIFICANTLY ENHANCE PART QUALITY BY MINIMIZING BARREL BOW

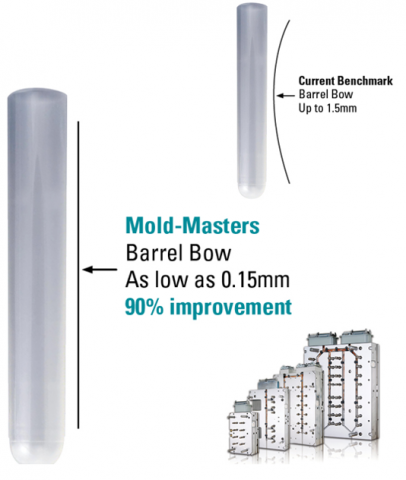

On recent blood vial applications that leveraged SYMFILL Technology, barrel bow was reduced by up to 90% (as little as 0.15mm) by eliminating core shift. SYMFILL Technology is exclusively available with Mold-Masters hot runner systems.

SYMFILL Technology significantly minimizes core shift to improve part quality (straightness) of cylindrical, center injected components having an aggressive L/D ratio. It achieves this by allowing the melt to enter the nozzle runner channel from multiple sides as opposed to the single-entry point of traditional designs. Examples of such components that would benefit from this technology include blood tubes, needle shields, over caps and other similar parts from the medical, cosmetic and stationary industries.

Minimizing barrel bow offers many downstream processing advantages which includes:

- Tubes roll concentrically in the labelling machine.

- Increases final stage throughput.

- Minimizes machine downtime.

About Mold-Masters

Mold-Masters is a leading global supplier of hot runners, controllers, auxiliary injection and co-injection systems. We design, manufacture, distribute, sell and service highly engineered and customized plastic processing equipment that caters to every market. Mold-Masters is credited for patenting the first commercially viable hot runner system in 1965. Today, Mold-Masters conducts business in over 100 countries and employs a diverse workforce that exceeds 2,150 professionals. Mold-Masters Global Headquarters is located in Georgetown, ON Canada.

Media Relations

Miki Bogar – Director, Global Marketing

905-877-0185 ext. 721

MBogar@moldmasters.com