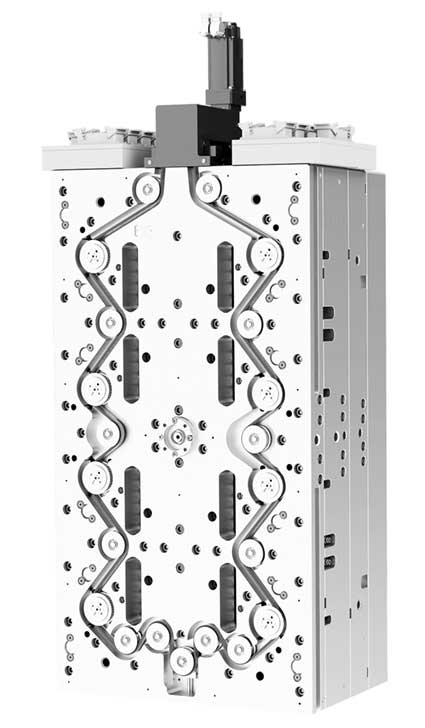

SERVO DRIVEN SYNCHRO PLATE SYSTEM ELIMINATES ACTUATION VARIABILITY

Precise simultaneous valve pin motion control for exceptional process stability. Easily adjust pin stroke, velocity, torque, timing, and position to improve mold balance and production quality. Compatible with all resins, E-Drive is ideal for high cavitation, technical, tight tolerance, and tight pitch applications across a wide range of industries.

Features

Servo Driven Actuation

- Unbeatable precision, control and reliability.

- Greatest level of process consistency and repeatability.

- Eliminate actuation variability.

Multi-Step Actuation Profiles

- Fully adjust opening and closing actuation variables.

- Optimize resin flow and balance.

- Greatly improves molded part quality.

- Prevents defects and scrap.

Exclusive Ball Screw & Belt Design

- Actuate up to 144 cavities with as little as one drive and plate.

- Highly mechanically efficient (rolling action eliminates friction).

- Minimizes wear to significantly extend service life.

- Consumes up to 60% less power (than traditional synchro plate designs).

All Electric

- Suitable for clean room applications.

- No risk of hydraulic mess or disposing of hazardous materials.

In-Press Access

- Easily maintain pins for adjustment and replacement.

- Eliminates the need for disassembly, minimizing downtime.

E-Drive Controller

- Compact and easy-to-use

- Contains the servo amplifiers

- Remote touch screen panel for set-up and monitoring

- Adjustable motion & speed profiles

- 4 configurable trigger inputs with time delay or IMM signal

- Adjustable Alarm and Warning limits