2K FLIP TOP BOTTLE CAP

CAP-THIN MOLDS TO OFFER COMPLETE MULTI-SHOT CAP & CLOSURE MOLDING SOLUTIONS WITH E-MULTI

Cap-Thin Molds, based out of Mississauga Ontario Canada, is a mold-maker that specializes in creating molds for caps, closures, and packaging. Recently, they have discovered Mold-Masters E-multi auxiliary injection units that quickly and economically convert any conventional injection molding machine to allow for multi-shot applications stating “E-Multi is a fantastic solution. It’s much more economical, with significantly shorter lead times, than conventional multi-shot injection machines”. Cap-Thin Molds has since adopted this technology to be able to offer their customers complete turnkey multi-shot molding solutions.

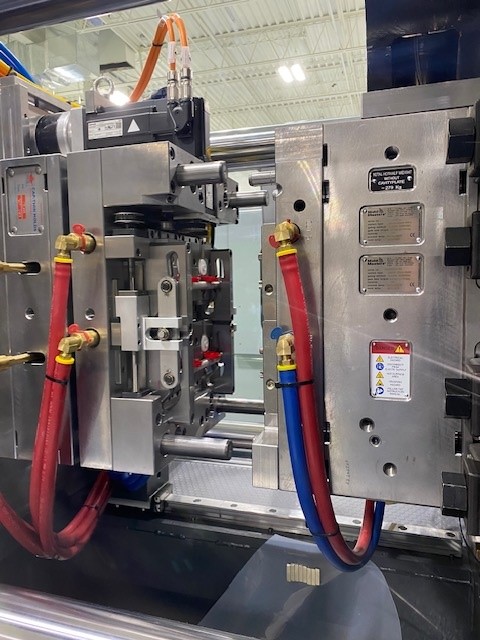

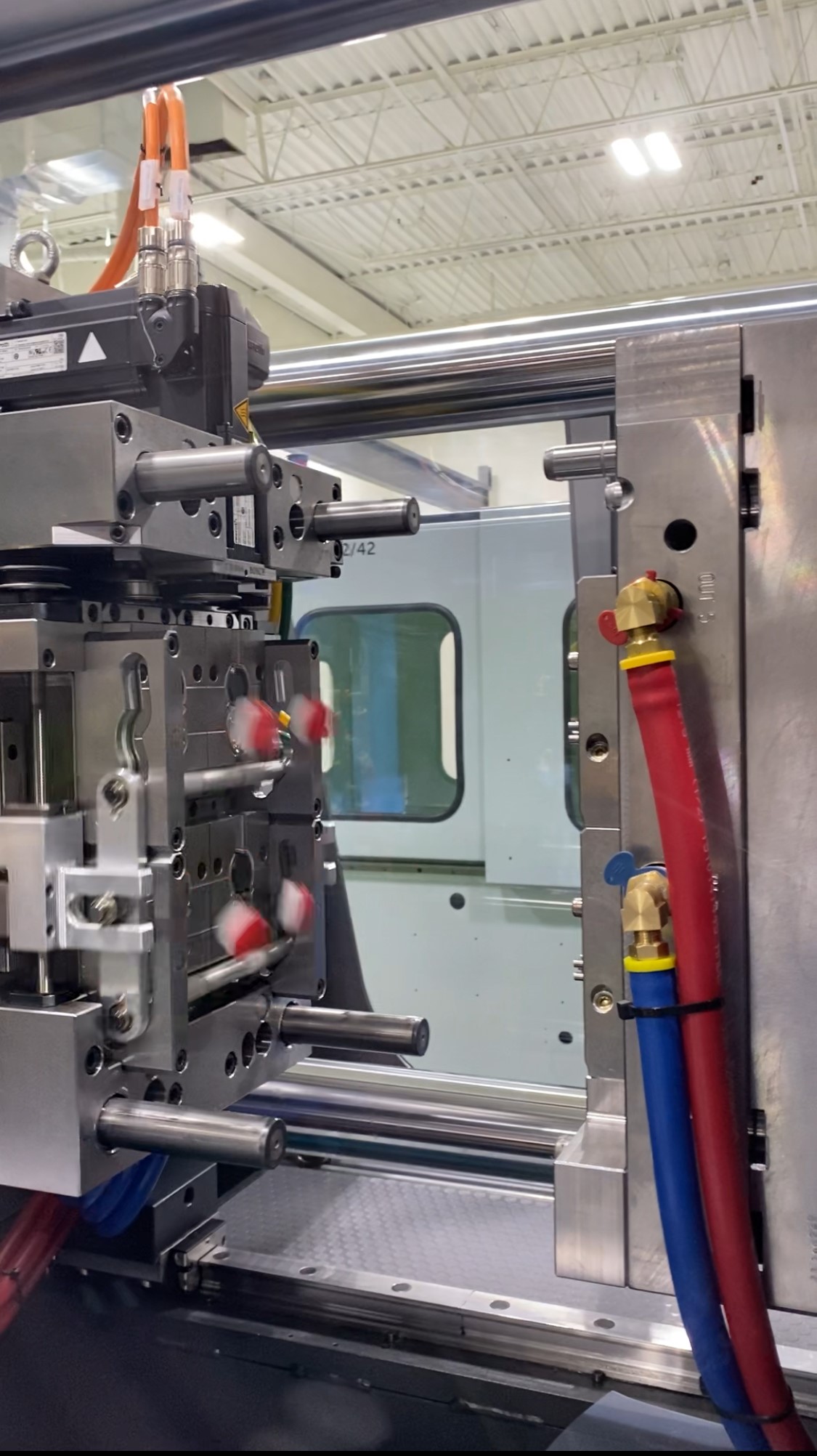

To highlight their capabilities, Cap-Thin created a demo mold which was on display at NPE 2024. This consisted of a 4-drop Mold-Masters Master-Series thermal gated hot half to produce 2-colour PP flip top lids. A special shut-off valve on the side of the mold controls the injection of the 2nd colour into the mold (white 1st shot, red 2nd shot) which allows the part to be produced in a single step process on one machine. The E-Multi unit was used to inject the 2nd shot and was vertically mounted on the mold. For demo purposes, the mold was run at a cycle time of less than 10 seconds however, faster cycle times can be achieved. This technology can be utilized by almost any cap application and can be applied to higher cavitation molds using any combination of coloured resin.

“E-MULTI IS A FANTASTIC SOLUTION. IT IS MUCH MORE ECONOMICAL, WITH SIGNIFICANTLY SHORTER LEAD TIMES, THAN CONVENTIONAL MULTI-SHOT INJECTION MACHINES."

Jessica, Cap-Thin Molds

Utilizing a multi-shot mold for this application saves additional production steps (manually moving the part to another mold) and cuts down on the number of machines required to make a multi-shot part. This specific mold design further highlights Cap-Thin Mold technology by incorporating two servo drives. These are used to control the automated mold functions (unscrew, close cap and eject). The servos are controlled by software in the injection molding machine.

Additionally, Cap-Thin Molds recently expanded their Technology center where they operate several injection machines from 150 tons to 450 tons to the benefit of their customers. This allows them to validate and approve tools before they are shipped to the customer. This saves their customers a considerable amount of time, money, and effort from having to ship a mold back and forth if any rework is requested by the customer.