Mold-Masters CO-INJECTION CONNECT package solution includes everything you need to easily and economically convert your existing single shot injection molding equipment over to produce co-injected parts. Mold-Masters Co-injection Technology is fully customizable to create a moisture, gas or light barrier for containers of all shapes and sizes for applications across any industry.

Features

HIGHLY ECONOMICAL

- Converting existing IMM equipment reduces your capital investment requirements by up to 84% (compared to purchasing a new multi-shot injection machine)

- Allows you to produce more economical high quality parts.

INDUSTRY LEADING CO-INJECTION TECHNOLOGY

- Proprietary nozzle designs allow two different resins to be combined into a single 3-layer melt stream.

- Incorporate high performance barriers as the core layer of packaging products to increase shelf life of contents by up to 5x (vs. monolayer parts).

- Provides a range of advantages and design flexibility over traditional monolayer parts.

PRECISE PROCESS CONTROL

- Enhance molded part properties by adjusting barrier layer placement and thickness.

- Ensures uniform distribution and prevents core layer breakthrough.

- Compatible with non-symmetrical shapes and designs.

PROVEN PERFORMANCE

- Take advantage of our extensive experience and successful track record.

- Each application is reviewed and optimized by our co-injection team.

GLOBAL SUPPORT NETWORK

- Mold with complete confidence knowing we´re with you every step of the way.

Specifications

Includes

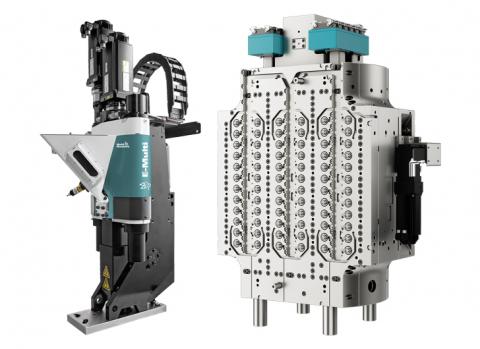

- Mold-Masters Co-Injection Hot Half

- E-Multi Co-Injection Auxiliary Injection Unit

- E-Multi Controller with 15" Touch Screen

- Engineering

- Testing Validation

- Start-up Support

- Training