PRESS RELEASE

Improve Environmental Stress Crack Resistance (ESCR) during CSD-cap manufacturing.

Mold-Masters®, a leading developer and supplier of hot runners, controllers, auxiliary injection, and co-injection systems for use in every market, is pleased to announce the creation and availability of the new Sprint APEX gate seal, which has been designed to help improve Environmental Stress Crack Resistance (ESCR) during the production of carbonated soft drink (CSD) caps.

controllers, auxiliary injection, and co-injection systems for use in every market, is pleased to announce the creation and availability of the new Sprint APEX gate seal, which has been designed to help improve Environmental Stress Crack Resistance (ESCR) during the production of carbonated soft drink (CSD) caps.

Achieving and maintaining a proper ESCR level is a Key Performance Indicator (KPI) for molding equipment that produces caps and closures. As such, it measures a CSD cap’s durability when it is placed under pressure or encounters severe operating conditions. The presence of injection flow lines can have a negative effect on ESCR performance in these situations, considering that if a single CSD cap fails, the entire batch may need to be returned to the molder.

With that in mind, molders are constantly looking to increase their ability to detect injection flow lines, while also enhancing safety factors, product performance and customer satisfaction. This can be a challenge as light weighting inevitably means a reduction in wall thickness that may compromise the CSD cap’s strength. Also, using Recycled and bio-based resins may not have the same strength and durability as conventional resins.

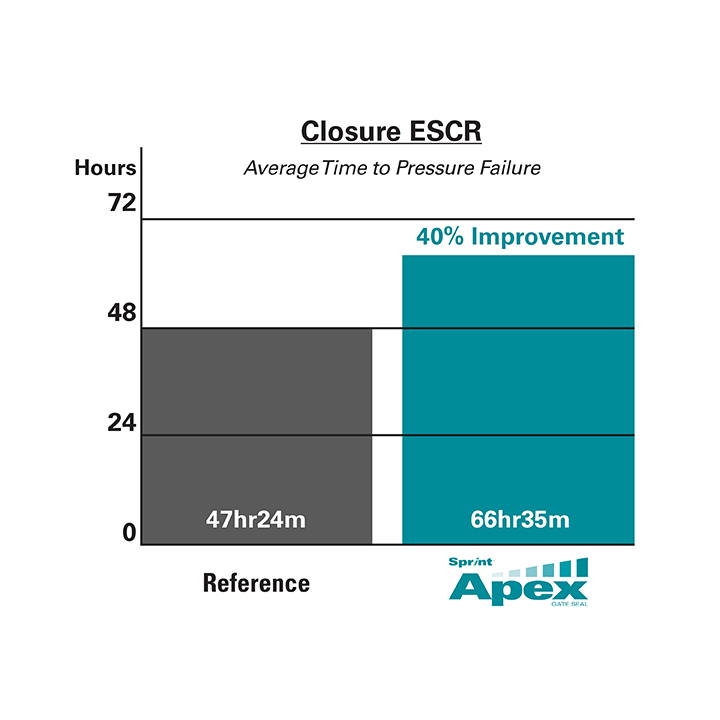

To help molders overcome these challenges, the Sprint APEX gate seal is designed to significantly minimize the presence of injection flow lines, which can increase the ESCR level of CSD caps by up to 40%, as determined and validated through third-party testing at Dow® Pack Studios. Additionally, in-field beta testing of the Sprint APEX gate seal on high-cavitation molding systems determined that stress cracking was eliminated on all dimple and non-dimple CSD-cap designs.

“The new Sprint APEX Gate Seal is the innovative solution that major global molders and converters have been waiting for,” said Thomas Bechtel, Global Sales Director, Packaging and Medical for Mold-Masters. “This solution will help eliminate spoilage during the CSD-cap production process, resulting in a more streamlined manufacturing operation that will result in a healthier bottom line for the manufacturer.”

The Sprint APEX Gate Seal offers a wide range of operational benefits to molders:

- Enables light weighting for cost savings and supports customers’ sustainability initiatives by reducing material usage without sacrificing CSD-cap durability.

- Enables the use of recycled and bio-based resins that don’t have the same ESCR durability as conventional resins.

- Improves color-change performance by up to 65% when compared to standard gate seals.

- Improves the appearance quality of caps that have difficulty hiding flow lines such as transparent decorative caps.

- Eliminates the use of vespel caps, which are a wear item, for reduced maintenance costs.

The new Sprint APEX Gate Seal is compatible with the Mold-Masters Sprint Hot Runner system as it features industry-standard cut-out and sealing dimensions that make it interchangeable with a standard hot-tip gate. Additionally, existing molds using competitive hot-runner systems can be retrofitted with a Sprint Hot Runner system that incorporates Sprint APEX Gate Seals. When retrofitting, customers can reuse their existing cavity inserts, making the conversion process more economical and shortening ROI.

For additional information about the new Sprint APEX Gate Seal and how it can benefit your CSD-cap molding operation, please contact your Mold-Masters technical expert at info@moldmasters.com or visit moldmasters.com.